SOURCETECH provides creative, flexible and cost-effective production solutions through our joint-venture facility in Qingdao, China and extensive network of manufacturing partners throughout Eastern China and Taiwan. We analyze the manufacturing process required for each project, then select suitable resources to cost-effectively deliver the quality product required to satisfy market expectations and achieve our client’s strategic objectives.

MANUFACTURING RESOURCES

SOURCETECH utilizes a variety of manufacturing resources at our joint-venture facility and over 90 supply chain partners’ locations throughout Eastern China and Taiwan. Once an appropriate production process is defined for each project, the most suitable resources are utilized to cost-effectively deliver the quality product needed to satisfy market requirements and achieve strategic client objectives. By managing the use of these resources, we can provide creative, flexible and low cost production solutions that include:

METAL FABRICATION, including:

- Bending (single & multiple angle)

- Cutting (brake, laser & water jet)

- Punching

- Stamping

- Assembly

- Other CNC & manual methods for steel, aluminum, copper, brass and other materials

WELDING, including:

- ARC

- GMAW or MIG

- GTAW or TIG

- Other CNC & manual methods for steel, aluminum, copper, brass and other materials

FOUNDRY, including:

- Die Casting

- Investment Casting

- Precision Casting

- Sand Casting

- Forging

- Other CNC & manual methods for iron, steel, aluminum, alloy, ferrous and other materials

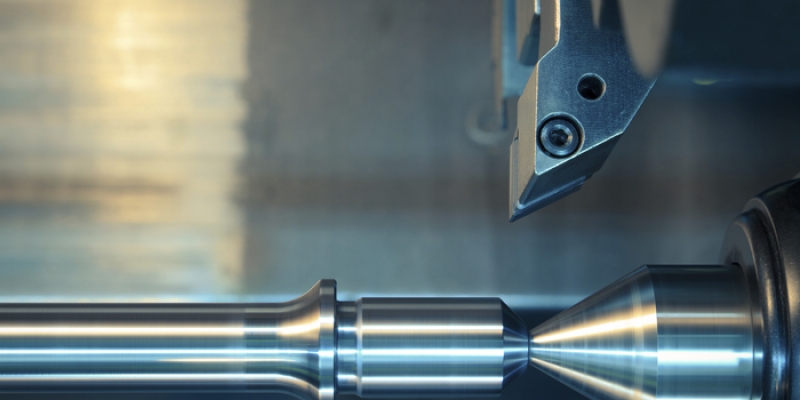

PRECISION MACHINING, including:

- Cutting (laser & water jet)

- Drilling

- Grinding

- Milling

- Turning

- Other CNC & manual methods for iron, steel, aluminum, alloy, ferrous and other materials

COATINGS & FINISHES, including:

- Anodizing (standard and high)

- Common and Specialty Paints (high temperature, marine, etc.)

- Enamel and other High Temp. Finishes

- Plating (chrome, cold/hot dip galvanizing, oxide, zinc, etc.)

- Powder Coatings

- Teflon & other Specialty Coatings

PLASTIC MOLDING, including:

- Blow molding

- Compression Molding

- Injection Molding

- Rotational Molding

- Other CNC & manual methods for Nylon, Polyethylene, Polypropylene and PVC materials

COMPOSITES FABRICATION, including:

- Autoclave

- Hand Lay-up (manual)

- Open-mold Spray-up

- Other fabrication methods for Carbon, Glass Fiber, Aramid and other composite materials

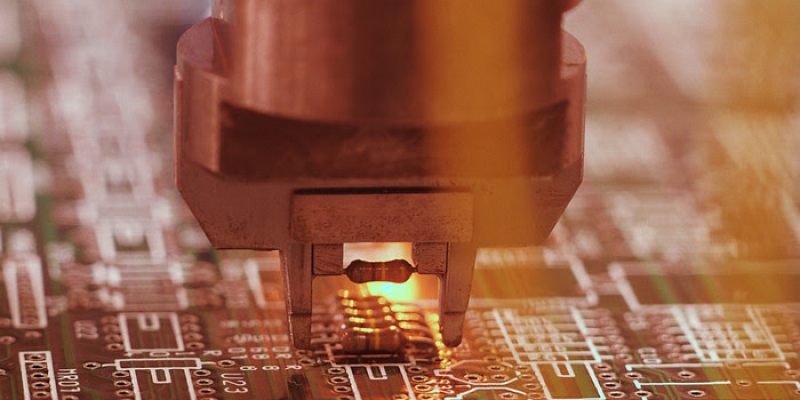

ELECTRONICS, including:

- Wiring Harnesses

- Circuit Board Assemblies

- Electro-mechanical Assemblies

TEXTILE PRODUCTION, including:

- Cut & Sew

- High Frequency Welding

- Luggage Assembly

- Specialty Fabric Production

- Other production methods for common and specialty woven and non-woven fabrics

PRODUCT ASSEMBLY, including:

- Automated, non-robotic

- Automated, robotic

- Manual

PACKAGING, including:

- Retail boxes and plastic packaging

- Commercial shipping cartons

- Industrial shipping crates & custom steel pallets

- Other specialized packaging for metal, plastic, electronic and other products

PRODUCTION TOOLING, including:

- Metal Fabrication Molds, Fixtures & Jigs

- Welding Fixtures & Jigs

- Assembly Fixtures & Jigs

- Plastic Molding Molds